Products

Boyser DS-M serie

Boyser peristaltic pump DS-M series

Operating principle of a peristaltic pump

The operating principle of a peristaltic pump attracts by its simplicity and advantages. A tubular element with accurate dimensions, made in different types of elastomer or thermoplastic, is housed into the pump body. When this tubular element is compressed by the rotary action of the rotor and its corresponding rollers or shoes, it recovers its initial shape creating a vacuum, suctioning this way the fluid. The fluid gets into the cavity formed by the rollers that press the tube, and is gently pushed to the outlet by the following roller. Therefore, the pump is a positive displacement volumetric pump with exceptional features.

Enkele applicaties voor Boyser slangenpompen type DS-M

- WATER AND SEWAGE TREATMENT: Sampling, chemicals dosing: Fenic Chloride, Sodium Hypochlorite, Sodium Bisulphite, etc… Abrasive products dosing: Lime slurry, Carbon slurry, Potassium Permanganate, etc… Polymers, aqueous ammonia, etc…

- FOOD AND BEVERAGE: Additives dosing in bakery, beverages, juices, sauces, enzymes, syrup, etc…

- CHEMICAL INDUSTRY: Dosing of all kinds of liquids in process, dyes, pigments, resins, latex, acids, inks, anti-foaming, glue, oils, etc …

- OTHER: Laboratory, paper industry, printing and packaging, ceramics, agriculture, mining, pharmaceutical industry, engineering, etc …

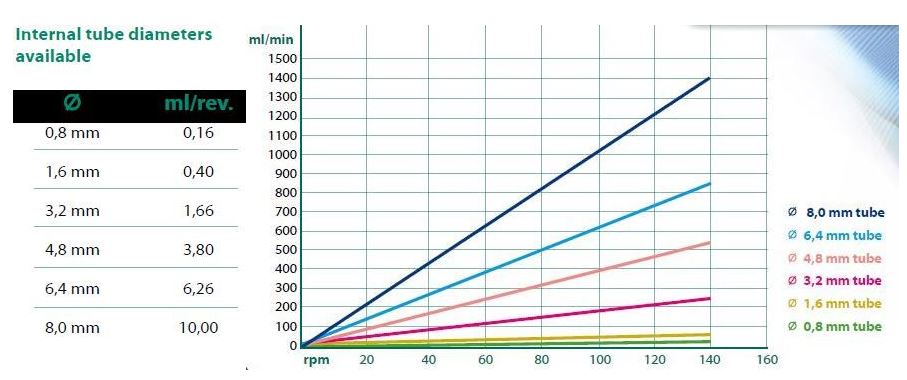

Available tubes:

- Silicona

- Norprene ® A-60-F

- Tygon ® LFL

- Norprene ® A-60-G

- Solva®

- Chem-Shure®