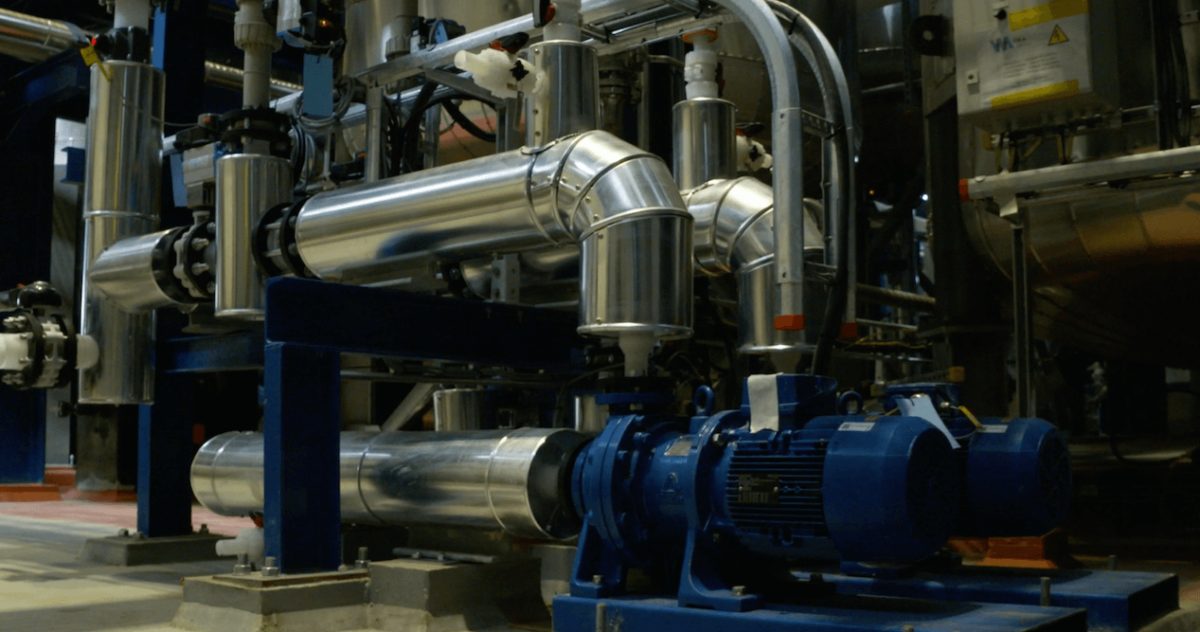

150 industrial pumps of every possible type for new chemical plant

It’s not often that our whole variety of industrial pumps is implemented in one single project. At the request of an engineering company, we matched every process of a chemical company’s new plant with the best possible industrial pump. And advised them on maintenance and spare part management.

The chemical company invested in the construction of a new factory department to diversify in the production of pure Molybdenum Oxide. The engineering company was contacted for the engineering of every aspect related to the production processes of that plant.

They in turn contacted us to select the best possible pump for every one of those processes. Just about industrial 150 pumps in total, including every possible type:

- magnetic drive pumps

- dosing pumps

- peristaltic pumps

- …

One single point of contact

“Partnering with us, offered three major advantages to the engineering company”, says Jan Van Gestel, managing director at Flowtec.

“Firstly, they were sure we could deliver all those different types of industrial pumps needed for this project. Even the ones that can handle abrasive fluids. With us, they had one single point of contact. And as this was a very elaborate project, I can imagine that as the main contractor, they already had plenty of contacts to oversee and manage.”

Proactive

“Secondly, we didn’t simply execute. We thought along. They handed us an overview of all the processes our industrial pumps had to handle. Going from the specific details about the chemicals, to the type of pump they had in mind for each process.”

“But from there, we dug deeper. As we always do. We also proposed alternative pump types for certain processes. We listed up the pro’s and con’s for every scenario. So we both were a 100% sure that we offered the client the best possible solution.”

Maintenance and spare part management

“And thirdly, we thought ahead. We wanted their clients’ processes to run smooth now, tomorrow and in the future. For example, we always take maintenance in consideration. We wanted to make it as easy as possible for the company’s technicians to keep the installation in great shape. Therefore, we tried to create a certain uniformity regarding the type of pumps and the brands we proposed. So they can more efficiently manage their spare parts.”

“Once everything was up and running, we sat down with the service technicians and engineers to talk them through the installations. What type of pump was linked to which certain process? Together, we dived into the technical details. And gave advice on the first maintenance and analyzed which spare parts were crucial to have in stock.”

Overview industrial pumps

- 75 Iwaki Mag Drive Pumps

- 40 Iwaki Dosing Pumps

- 4 AODD Pumps

- 9 Stübbe X-class Heavy Duty Pumps

- 4 Boyser Peristaltic Pumps

- 5 OBL Dosing Pumps

- 9 Slurry Pro Pumps